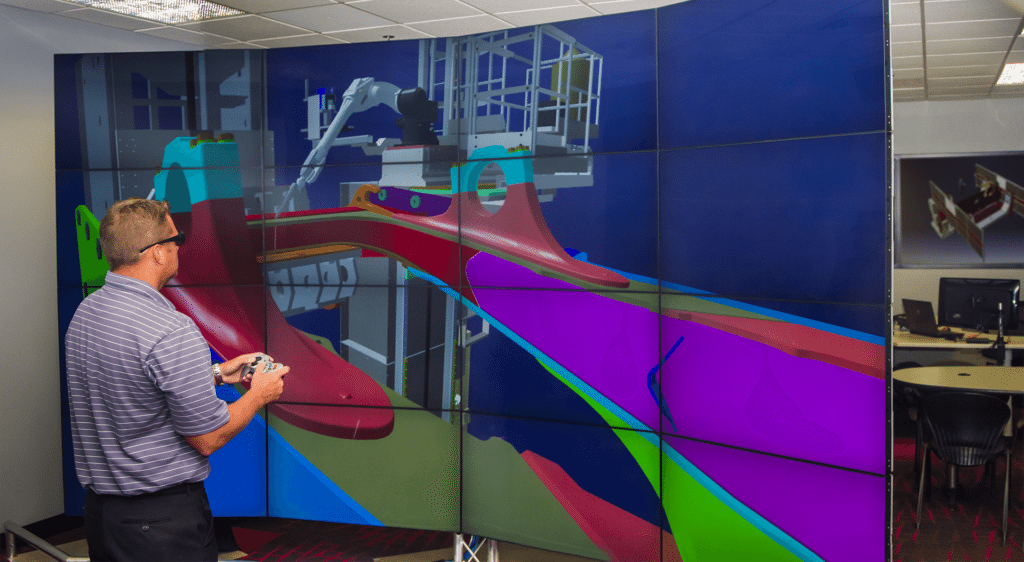

Robot simulation has been around for decades, but it wasn’t always the go-to solution for robotic integration. In the early days, when robots were rare and costly, simulations were commonly used by research institutions to test ideas and concepts without the need for physical prototypes. However, as the 1990s rolled in and robot prices dropped significantly, many researchers shifted their focus from virtual models to real-world testing. Simulations lost some of their popularity during this time. But with the rapid growth of computing power in recent years, the private sector has rediscovered the value of robot simulation, using it for a variety of applications. This shift marks an important evolution in robotic automation. Before diving into the benefits, it’s helpful to understand how these virtual solutions actually work. Virtual Solutions Centers are part of the services offered by robotic systems integrators. These centers aim to create a full-scale digital replica of a robotic system and its environment, including all relevant variables that could affect performance. This allows for a proof of concept to be demonstrated before any physical installation takes place. By simulating real-world conditions, these centers can replicate the actual application scenario as accurately as possible. Often, the programming developed in the simulation can be directly transferred to the real robot, reducing setup time and ensuring a smooth transition once the system is deployed. Virtual Solutions Centers play a crucial role in robotic integration for several reasons. First, they allow for the validation of design concepts before any hardware is built, which helps identify potential flaws early on and ensures the final system meets expected productivity goals. Additionally, simulations enable integrators to experiment with new technologies in a safe and controlled environment, leading to more efficient and innovative solutions. This not only reduces development costs but also lowers the barriers to automation investment, making advanced robotics more accessible to a wider range of businesses. The use of Virtual Solutions Centers is becoming increasingly vital in the robotics and automation industry. Both manufacturers and integrators can benefit from leveraging these powerful tools to streamline processes and drive innovation. To explore more about how robot simulations work and see real-world applications, continue reading about Genesis’ Virtual Solutions Center. Thermoforming Packaging Machine Thermoforming Packaging Machine,Thermoforming Vacuum Packing Machine, Thermoforming Modified Atmosphere (MAP) Packaging Machine, Thermoforming Vacuum Skin (VSP) Packaging Machine ZHUCHENG YIKANG FOOD PACKING MACHINERY CO., LTD. , https://www.yikangmachinery.comVirtual Solutions Center: How Does Robot Simulation Aid in Robot Integration?

What Are Virtual Solutions Centers and How Do They Function?

Why Are Virtual Solutions Centers Important?

Very well explained the importance of virtual solutions for robot simulations. It also helped kids to understand the world of robotics at the beginning level. Thanks for sharing useful information.