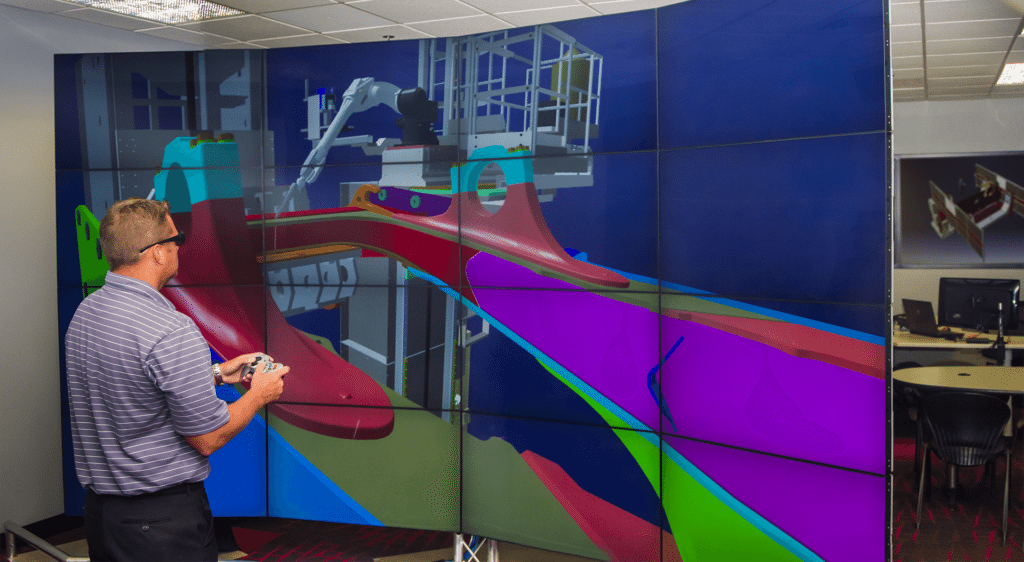

Robot simulation has been around for decades, but it wasn’t always the go-to solution for robotic integration. In the early days, when robots were rare and expensive, simulations were commonly used by research groups to test ideas and concepts before building actual systems. As the 90s rolled in, robots became more affordable, and researchers began preferring real-world testing over virtual environments. This led to a decline in the use of simulation tools. However, with the rise of powerful computing and advanced software in recent years, the private sector has rediscovered the value of robot simulation. This shift is driving significant changes in how robotics are integrated into manufacturing and automation. Before diving into the details, let’s take a closer look at how virtual solutions centers function and why they matter. Virtual Solutions Centers (VSCs) are part of the services offered by many robotic system integrators. These centers aim to create a full digital replica of a robotic system and its environment, including all relevant process variables, to validate the concept before physical implementation. By simulating real-world conditions as accurately as possible, VSCs allow engineers to test and refine robotic processes virtually. This means that once the robot is deployed, its programming is often already optimized and ready to go, reducing downtime and improving efficiency. VSCs play a crucial role in robotic integration for several reasons. First, they provide a proof of concept before any hardware is built, which helps identify design flaws early on and ensures the system meets productivity goals. Additionally, these centers enable integrators to experiment with new technologies in a safe, controlled environment. This not only improves system performance but also lowers the risk associated with implementing complex robotic solutions. As a result, companies are more willing to invest in automation, leading to faster innovation in the robotics industry. The adoption of Virtual Solutions Centers is transforming the way robots are designed, tested, and deployed. Whether you're a manufacturer or an integrator, leveraging advanced simulation tools can offer a competitive edge in today's fast-paced industrial landscape. To learn more about how Genesis’ Virtual Solutions Center is helping businesses integrate robots efficiently, continue reading our detailed guide. Continuous Belt Type Vacuum Packaging Machine Continuous Belt Type Vacuum Packaging Machine, Transmission Type Vacuum Packaging Machine,Conveyor Belt Type Vacuum Packing Machine,Belt Type Vacuum Packaging Machine ZHUCHENG YIKANG FOOD PACKING MACHINERY CO., LTD. , https://www.yikangmachinery.comVirtual Solutions Center: How Does Robot Simulation Aid in Robot Integration?

What Are Virtual Solutions Centers and How Do They Work?

Why Are Virtual Solutions Centers Important?

Very well explained the importance of virtual solutions for robot simulations. It also helped kids to understand the world of robotics at the beginning level. Thanks for sharing useful information.