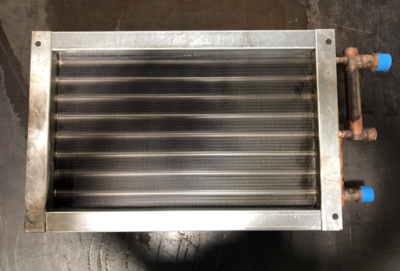

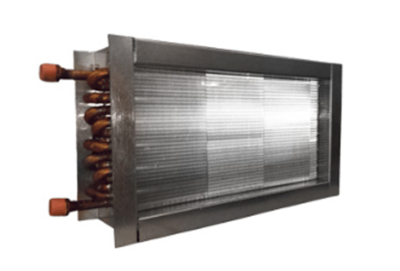

As the weather cools down, replacing hot water coils becomes a common task. Investing in a high-quality replacement hot water coil can significantly enhance efficiency while keeping costs in check... THE BASICS OF HOW A HOT WATER COIL OPERATES Hot water coils serve as efficient heat exchangers, transferring thermal energy from heated water to incoming air. These coils typically consist of multiple rows of copper tubes embedded within aluminum fins, all securely fastened together via expansion. As air flows over the coil, the heat from the water inside the tubes warms the air, facilitating an effective heat exchange process. Hot water coils find diverse applications, including energy recovery systems, space heating, and boosting the temperature of air in specific areas. Their versatility makes them indispensable in both residential and industrial settings. DESIGN AND MATERIAL VARIATIONS IN HOT WATER COILS While the basic structure of hot water coils remains consistent, their materials and design specifications vary based on the intended use. Most commonly, these coils feature one to three rows of tubes, though custom designs can exceed this range. Copper tubes and aluminum fins are standard, with tube diameters typically measuring 5/8", 1/2", or 3/8". The water passing through these tubes can reach temperatures up to 200°F. In environments prone to corrosion or in industries such as food processing, coils may incorporate stainless steel components to ensure durability and longevity. Some hot water coils come equipped with headers, while others do not. Those without headers are sometimes called booster coils, reheat coils, or heater core coils. Booster coils are particularly useful for restoring warmth to air that has cooled during its journey through ducts, especially in larger buildings where the air handler is located far from the heating zones. Over time, we’ve crafted countless custom and OEM replacement coils, ranging from compact units suitable for small spaces to massive installations spanning entire walls. Many of these replacements cater to major brands like Carrier, Trane, York, and others. FINDING THE RIGHT SIZE FOR YOUR COIL Replicating hot water coils accurately ensures precise fit and performance. For replacement purposes, measuring the fin height, fin length, and counting the number of rows wide is essential. When designing a new coil, additional factors such as CFM (face velocity can reach up to 1250 ft/m), entering dry bulb temperature, gallons per minute (GPM), and desired capacity/leaving air temperature must be considered. If you're taking your own measurements, refer to our blank coil drawing resources for detailed guidance on recording construction specifics and sizing. EASY ORDERING PROCESS FOR HOT WATER COILS Nationwide Coils provides extensive customization options for hot water coils, along with a selection of stock sizes tailored to meet commercial and industrial heating requirements. Whether you need a standard replacement or a bespoke solution, our team is ready to assist. Feel free to contact us via email if you have questions about ordering a hot water coil or any other replacement or custom coil. Our dedicated professionals aim to simplify your procurement process. Weak Base Anion Exchange Resin Weak Base Anion Exchange Resin,Anion Ion Exchange Resin,Anion Resin,Food Grade Anion Exchange Resin Henan Comcess Industry Co., Ltd. , https://www.comcessresins.comA Deeper Dive into Replacement Hot Water Coils

Written by: Andre Ostacoli

Nationwide Coils, Inside Sales Manager