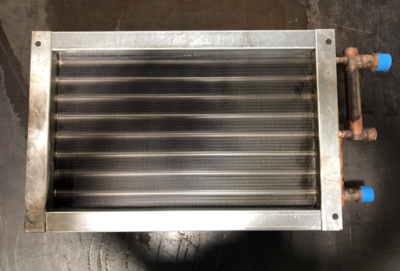

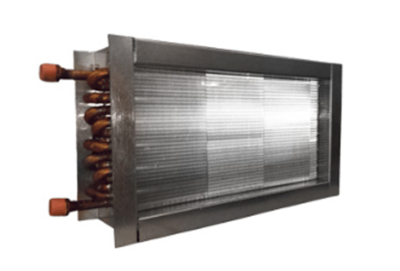

As colder weather sets in, the demand for hot water coils increases. Investing in a reliable replacement hot water coil is an efficient way to maintain optimal system performance... THE BASICS OF HOT WATER COILS Hot water coils serve as essential components in HVAC systems, transferring heat from water to air. These tube-fin heat exchangers feature rows of tubes embedded within fin surfaces. As cool air moves over the coil, it absorbs heat from the water circulating inside the tubes. This process ensures efficient heating of indoor spaces. Hot water coils find application in various settings, such as energy recovery, preheating, booster heating, and general comfort heating. They play a critical role in maintaining comfortable environments during colder months. DESIGN AND MATERIALS While hot water coils share a similar structure, their materials and specifications vary based on specific applications. Most commonly, they consist of one to three rows of tubes, though larger units are also available. The standard combination includes copper tubes paired with aluminum fins, with tube diameters typically measuring 5/8", 1/2", or 3/8". The water flowing through these tubes can reach temperatures up to 200°F. In harsh environments or industries like food processing, corrosion-resistant materials such as stainless steel may be used. This enhances durability and longevity under challenging conditions. Some hot water coils come equipped with headers, while others do not. Those without headers might be labeled as booster coils, reheat coils, or heater core coils. Booster coils are particularly useful for restoring warmth to air that has cooled during its journey through ductwork. In some cases, a header may be present on both ends, especially when replacing certain brands like Heatcraft™ or McQuay®. Throughout our history, Nationwide Coils has manufactured countless custom and original equipment manufacturer (OEM) replacement hot water coils. These range from compact designs suitable for smaller spaces to large-scale units rivaling walls in size. We’ve worked extensively with top brands such as Carrier®, Trane®, and York® to ensure compatibility and performance. MEASURING FOR REPLACEMENT COILS Replacing a hot water coil requires precise measurements to guarantee proper fit and functionality. For existing coils, we assess fin height, fin count, and row width. For new installations, additional factors like CFM (up to 1250 ft/min), entering dry bulb temperature, gallons per minute (GPM), and desired capacity/leaving air temperature must be considered. If you’re taking your own measurements, refer to our blank coil drawings page to document construction details accurately. EASY ORDERING PROCESS At Nationwide Coils, we pride ourselves on offering flexible customization options alongside a selection of stock sizes tailored to meet diverse commercial and industrial heating requirements. Whether you need a straightforward replacement or a fully customized solution, our team is ready to assist. Feel free to reach out via email if you have questions about ordering a hot water coil or any other type of replacement coil. Our dedicated professionals are committed to simplifying your experience. Specialty Resins,Adsorbent Resin,Anion Exchange Adsorbent Resin,Catalytic Resin Henan Comcess Industry Co., Ltd. , https://www.comcessresins.comGetting Acquainted with Replacement Hot Water Coils

Written by: Andre Ostacoli

Nationwide Coils, Inside Sales Manager