Table of contents

What is Seamless Tube

What is Welded Tubes

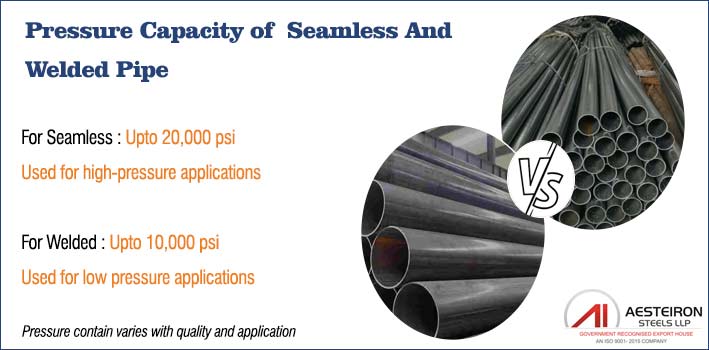

Pressure Capacity of Seamless And Welded Tubing

Seamless vs Welded Tubing

Difference Between ERW and Seamless Tube Price

Advantages and Disadvantages of seamless and welded tube

Seamless Tubing Sizes

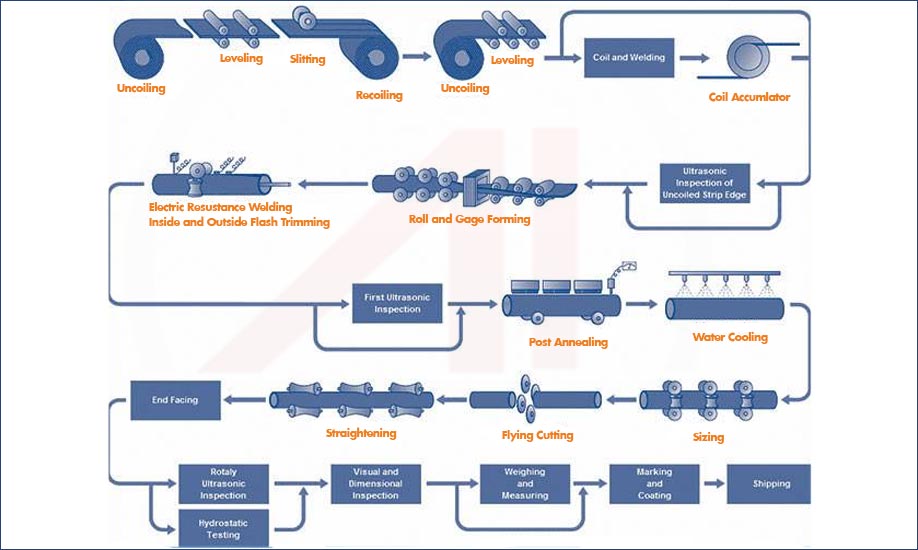

Seamless Steel Tubes Manufacturing Process

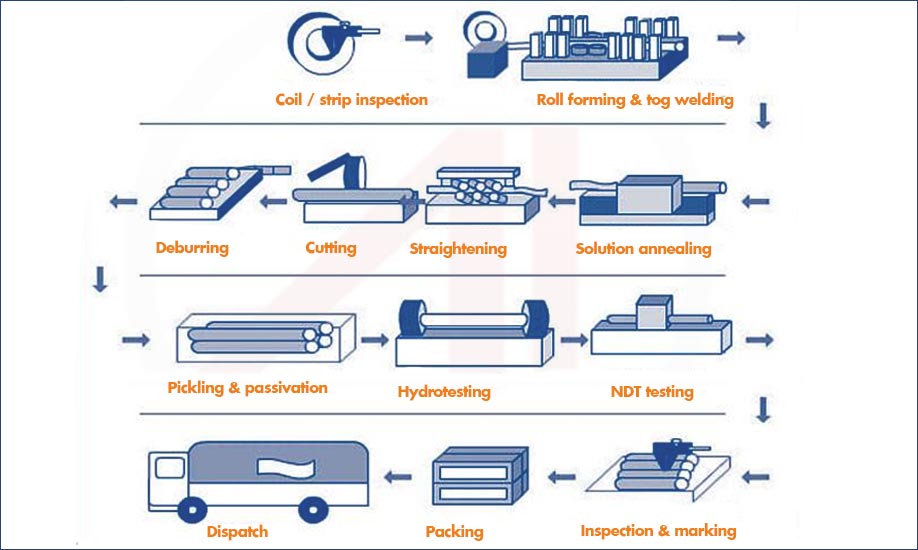

Welded Steel Tube Manufacturing Process

Seamless Tubing vs DOM Tubing

Seamless Steel Tube Uses

Application for Welded Round Tubing

Mechanical Properties of ERW vs Seamless Tube

Finish for Welded and Seamless Tubes

Seamless Tube Weight Chart

SMLS Tube Extrusion Process

Welded Tube Types

Seamless tubes are designed to withstand higher pressure than welded tubes

One of the key advantages of seamless tubes is that they do not have a weld seam, which makes them more resistant to stress and potential failure points. This feature allows them to handle higher pressure applications with greater reliability. Below is a detailed comparison of the pressure ratings for both types of tubes.

Pressure Capacity of Seamless And Welded Tubing

Welded tubes often have larger diameters and thinner walls

This design makes them ideal for architectural and construction applications where precise dimensions are needed. Because they can be manufactured more quickly, they are also easier to customize for specific projects. As a result, you can achieve larger diameters and thinner walls tailored to your unique requirements.

Seamless vs Welded Tubing

Description

Seamless Tubing

Welded Tubing

Manufacturing Process

Seamless tubes are made from a solid billet that is heated and extruded into a tubular shape without any weld seams.

Formed from flat metal strips that are rolled and welded along their length.

Length

Shorter in length

Available in long continuous lengths

Strength

Stronger

Lower compared to seamless

Uniformity

More uniform wall thickness

Wall thickness may vary slightly

Applications

Used for high-pressure applications and critical structural components.

Commonly used in less critical applications

Corrosion Resistance

More corrosion-resistant.

Less corrosion resistance.

Cost

More expensive

Less expensive

Manufacturing Flexibility

Less flexible

More flexible

Surface Quality

Rough because of extrusion process

Smooth high-quality surface

Surface Finish

Smoother finish and few surface defects.

Surface finish can be less consistent due to the welding process

Ovality

Provide better ovality and roundness

Poor ovality and roundness

Inspection & Testing

Requires more rigorous testing to ensure quality and strength.

May require less rigorous testing

Internal surface check

Not possible

Checked before manufacturing

Size Range

Available in a more limited range of sizes than welded tubing.

Can be produced in a large range of sizes and lengths.

Welded tubing is generally less expensive than seamless tubing

The production of welded tubes is faster and more cost-effective, making them a popular choice for industries that require low to medium pressure applications. The lower cost is also due to reduced labor and material expenses during the manufacturing process.

Difference Between ERW and Seamless Tube Price

Seamless Tube

ERW Steel Tube

More expensive : can be 1.5 to 3 times the cost of welded tubes

Less expensive : more affordable by 30% to 60% compared to seamless tubes

Factor affecting : Manufacturing Process, Quality, Production Costs, Demand

Advantages and Disadvantages of seamless and welded tube

The Pros and Cons of Hot Finished Seamless Type Tubes

Pros

Cons

Excellent corrosion resistance

Expensive

Good Durability

Difficult to manufacture

High pressure rating

Not ideal for thin wall large diameter tubes

Good Purity

Longer lead times

Ideal for critical applications

Â

The Pros and Cons of Welded Tubes

Pros

Cons

Better lead times

Suitable for Heavy wall applications

Less Expensive

Less corrosion resistant

Available in long lengths

Slight impurities

Thinner wall

Stress concentration

More consistent concentricity

Â

Tighter tolerances

Â

Seamless Tubing Sizes

NPS

Schedule

DN

OD

Wall thck

Weight

[inch]

[inch]

[lbs/ft]

1/8

10

6

.405

.049

.19

Â

40

Â

Â

.068

.24

Â

80

Â

Â

.095

.31

1/4

10

8

.54

.065

.33

Â

40

Â

Â

.088

.42

Â

80

Â

Â

.119

.54

3/8

10

10

.675

.065

.42

Â

40

Â

Â

.091

.57

Â

80

Â

Â

.126

.74

1/2

5

15

.84

.065

.54

Â

30

Â

Â

.095

.76

Â

40

Â

Â

.109

.85

Â

160

Â

Â

.188

1.31

3/4

5

20

1.05

.065

.69

Â

30

Â

Â

.095

.97

Â

80

Â

Â

.154

1.47

Â

160

Â

Â

.219

1.94

1

5

25

1.315

.065

.87

Â

10

Â

Â

.109

1.41

Â

40

Â

Â

.133

1.68

Â

160

Â

Â

.25

2.84

1 1/4

5

32

1.66

.065

1.11

Â

30

Â

Â

.117

1.93

Â

80

Â

Â

.191

3

Â

160

Â

Â

.25

3.76

1 1/2

5

40

1.9

.065

1.28

Â

10

Â

Â

.109

2.09

Â

40

Â

Â

.145

2.72

Â

80

Â

Â

.2

3.63

Â

160

Â

Â

.281

4.86

2

5

50

2.375

.065

1.61

Â

Â

Â

Â

.109

2.64

Â

Â

Â

Â

.141

3.36

Â

40

Â

Â

.154

3.65

Â

Â

Â

Â

.188

4.39

Â

80

Â

Â

.218

5.02

Â

Â

Â

Â

.281

6.28

Â

160

Â

Â

.344

7.46

2 1/2

5

65

2.875

.038

2.47

Â

10

Â

Â

.12

3,53

Â

Â

Â

Â

.125

3.67

Â

Â

Â

Â

.156

4.53

Â

Â

Â

Â

.188

5.4

Â

40

Â

Â

.203

5.79

Â

80

Â

Â

.276

7.66

Â

160

Â

Â

.375

1 .01

3

Â

80

3.5

.083

3.03

Â

10

Â

Â

.12

4,34

Â

Â

Â

Â

.141

5.06

Â

Â

Â

Â

.172

6.11

Â

40

Â

Â

.216

7.58

Â

Â

Â

Â

.281

9.66

Â

80

Â

Â

.3

1 .25

Â

160

Â

Â

.438

14.32

3 1/2

5

90

4

.083

3.48

Â

10

Â

Â

.12

4.98

Â

Â

Â

Â

.141

5.81

Â

Â

Â

Â

.172

7.03

Â

40

Â

Â

.226

9.11

Â

Â

Â

Â

.281

11.16

Â

80

Â

Â

.318

12.5

4

5

100

4.5

.083

3.92

Â

10

Â

Â

.12

5.62

Â

Â

Â

Â

.141

6.56

Â

Â

Â

Â

.172

7.95

Â

Â

Â

Â

.203

9.32

Â

40

Â

Â

.237

1 .79

Â

Â

Â

Â

.281

12.66

Â

80

Â

Â

.337

14.98

Â

160

Â

Â

.531

22.51

Seamless steel tube is extruded and drawn from a billet while welded tube is manufactured from a strip

The difference between the two tubes lies in their manufacturing processes. Seamless tubes do not have any weld seams, which gives them higher strength and makes them suitable for high-pressure conditions. In contrast, welded tubes have welds, which can reduce their strength and make them more appropriate for applications with medium to low pressure conditions.

Seamless Steel Tubes Manufacturing Process

Welded Steel Tube Manufacturing Process

Seamless Tubing vs DOM Tubing

Description

Seamless Tube

DOM Tubing

Manufacturing Process

Made from a solid billet

Starts as a welded tube, then drawn over a mandrel

Advantages

High strength and durability

Good dimensional accuracy

Strength

Higher

Improved strength compared to standard welded tubes, but not as stronger than seamless tubing

Weld Seams

No weld seams

Originally welded, but weld seam is removed during the mandrel process

Dimensional Accuracy

High

Very high

Surface Finish

Varies

smooth and uniform after mandrel drawing

Cost

More

Less

Seamless Steel Tube Uses

Aerospace

Oil and gas

Structural components in demanding environments

High-pressure hydraulic systems

Seamless annealed tubing is more expensive than welded round tubing

Seamless annealed tubing goes through multiple processes, which increases its cost. These processes take longer and involve higher labor and machining costs, making seamless tubing more expensive than welded tubing.

Application for Welded Round Tubing

General structural applications

Piping and tubing in less demanding environments

Automotive components

Furniture and general manufacturing

Mechanical Properties of ERW vs Seamless Tube

Property

Seamless Tubes

ERW Steel Tubes

Tensile Strength

Higher than welded

Lower than seamless

Yield Strength

Consistent across the entire tube

May vary

Elongation

Better

Can be reduced at the weld seam and heat-affected zones – HAZ

Impact Toughness

Higher

Lower

Fatigue Resistance

Higher

Lower

Hardness

Typically more consistent throughout the tube.

Show variation

Weld Integrity

N/A

Quality of the weld can impact overall mechanical properties

Finish for Welded and Seamless Tubes

Seamless tubing

Cold Drawn Finish

Hot Finished

Polishing

Passivation

Coating

Welded tubing

Heat Treatment

Descaling

Polishing

Coating

Anodizing

Seamless Tube Weight Chart

Nominal Tube Size

inch

1/8

1/4

3/8

1/2

3/4

1

1.1/4

1.1/2

2

2.1/2

3

4

5

6

8

10

12

mm

3

6

10

15

20

25

32

40

50

65

80

100

125

150

200

250

300

Outside Diameter

mm

10.3

13.7

17.1

21.3

26.7

33.4

42.2

48.3

60.3

73

88.9

114.3

141.3

168.3

219.1

273.1

323.8

Sched 5 S

Weight in kgm

0.2

0.37

0.47

0.8

1.03

1.3

1.65

1.91

2.4

3.69

4.51

5.84

9.47

11.32

14.79

22.63

31.25

WT in mm

1.2

1.2

1.2

1.65

1.65

1.65

1.65

1.65

1.65

2.11

2.11

2.11

2.77

2.77

2.77

3.4

3.96

Sched 10 S

Weight in kgm

0.28

0.49

0.63

1

1.28

2.09

2.7

3.11

3.93

5.26

6.45

8.36

11.57

13.84

19.96

27.78

36

WT in mm

1.24

1.65

1.65

2.11

2.11

2.77

2.77

2.77

2.77

3.05

3.05

3.05

3.4

3.4

3.76

4.19

4.57

Sched 20 S

Weight in kgm

0.33

0.58

0.74

1.07

1.52

1.94

2.9

3.55

4.24

6.81

8.37

12.18

16.8

25.36

33.31

41.77

49.7

WT in mm

1.5

2

2

2.3

2.55

2.55

3

3

3

4

4

4.5

5

6.35

Interlock Bottom Bracket

· PREMIUM QUALITY: Precision machining, with high quality assurance of comprehensive performance.

· HIGH RELIABILITY: Professional manufacturing, stable characteristics and high reliability.

· HIGH QUALITY MATERIAL: Made of high quality alloy material, sturdy, durable and long service life.

· MORE CONVENIENT: Simple design, easy to install and operate, convenient to use.

· STURDY AND DURABLE: The special design of the threaded bottom bracket, where the cups are threaded and screwed together within frame, ensures avoid any squeaking.

Interlock Bottom Bracket,Aluminum Cup Bottom Brackets,Press Fit Bottom Bracket,Bicycle Child

Shenzhen Gineyea Technology Co., LTD. , https://www.gineyea.com

Post navigation